When you're diving into the world of 3D printing, understanding the different types of resin can really help you choose the right one for your project. The resin you pick impacts everything from the final look of your print to how strong it will be. Let’s break down some common types.

Standard resin is your go-to for most applications. It’s perfect for creating detailed models or prototypes. This type delivers smooth finishes and vibrant colors, so everything looks great right off the printer. If you're making things like miniatures, board game pieces, or even jewelry, standard resin does the trick well.

If you need something tougher, check out tough resin. It’s designed to handle stress, so it's ideal for functional parts or parts that need to survive some wear and tear. Think of it as a more durable option that still captures great detail. Ideal for gears, brackets, and other parts that you want to last.

Have an eye for color? Color resin is also available and can add a fun twist to your prints. With various shades and some even allowing you to mix them for unique colors, your creativity can really shine. Perfect for art pieces or any project where aesthetics matter.

If you're into making intricate designs, flexible resin is a game-changer. It gives you that rubbery feel, making it perfect for things like phone cases, wearable items, or anything else that should bend without breaking. You'll love the versatility it offers!

Choosing the Right Resin for Your Project

Picking the right resin for your 3D printing project can really make a difference in the final result. With all the options out there, it's easy to feel a bit overwhelmed. But don’t worry! Let’s break it down together so you can find the perfect match.

First up, think about what you’re printing. Are you making models for display, or do you need something super sturdy? For detailed miniatures or models, a standard resin is often great. It gives you sharp features and smooth surfaces. If you need extra toughness, like for functional parts, look for industrial or toughened resins. They handle stress better and won’t crack easily.

You’ll also want to consider the curing time. Some resins cure quickly, which can speed up your production, while others take their time and need a bit more patience. If you’re in a hurry, fast-curing options are your friend. Just keep in mind that they often come with a trade-off in feature detail.

Don’t forget about the color and finish! Resin comes in all sorts of shades and finishes, from clear to opaque and glossy to matte. Choose something that fits your vision. If you're looking to paint your project later, a grey or white resin might be best to start with.

Finally, safety is key. Always check if the resin you want is safe to handle, especially if you're working in a small space. Some resins give off fumes, so a good workspace with proper ventilation is important. Wear gloves and goggles when working to keep yourself safe while creating amazing things!

Benefits of Using 3D Resin Printing

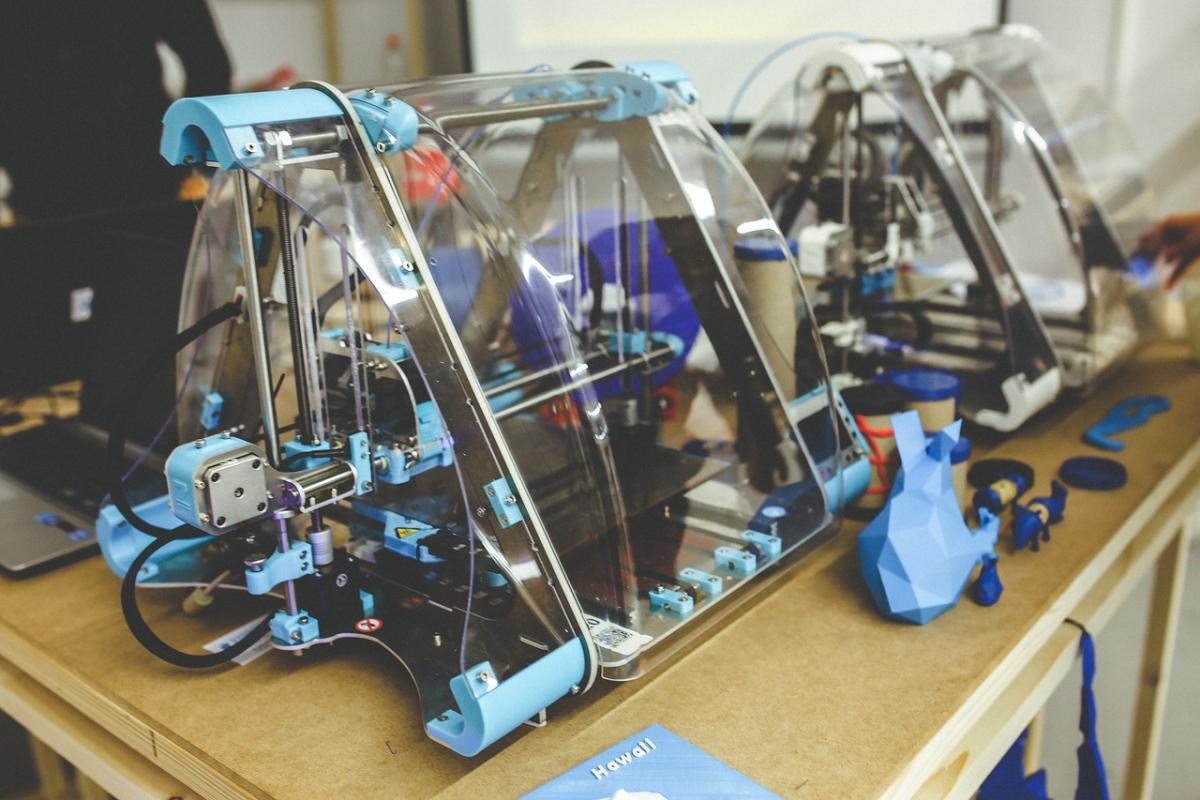

3D resin printing brings a ton of perks that traditional printing methods just can't match. For starters, it delivers amazing detail and precision. If you want sharp edges and intricate designs, resin is where it shines. You can create pieces with tiny features that stand out, whether you're making jewelry or miniatures.

Another cool thing about 3D resin printing is the variety of materials available. You can choose from a range of resins designed for different uses. Need something durable and tough? There’s a resin for that. Looking for something flexible? Yep, you’ll find options. This flexibility means you can tackle a lot of different projects without needing multiple printers.

Speed is a big win, too. Resin printers can churn out models faster than filament-based ones, especially for smaller parts. If you're in a race against time, that's a huge advantage. Plus, the prints usually require less post-processing, saving you even more time.

And let’s not forget the fun factor. Working with resin is like a creative playground. You get to experiment with colors and finishes that make your projects pop. It’s super satisfying to see your design come to life in such vibrant detail!

Tips for Working with 3D Resins

When you dive into the world of 3D resins, there are a few tips to keep in mind that can really make your experience smoother. First off, always wear gloves when handling resin. It can be pretty messy, and you definitely don’t want it on your skin. A simple pair of nitrile gloves will do the trick.

Next, work in a well-ventilated area. Some resins can give off strong fumes that you don’t want to breathe in. Open windows or use a fan to keep the air flowing. If you’re really serious about it, consider using a respirator mask for extra protection.

Make it a habit to clean your tools right after use. Resin can harden quickly, and if you leave it to set on your mixing sticks or containers, it’s going to be a pain to clean. Isopropyl alcohol (70% or higher) works great for cleaning up spills and tools.

Temperature matters! Keep your resin in a cool, dry place. If it’s too hot, it can become too runny, and if it’s too cold, it might not cure properly. Aim for a comfortable room temperature when working on your prints.

Lastly, experiment with small test prints before committing to larger projects. This way, you can get a feel for how your chosen resin behaves. It’s much better to troubleshoot on a small scale than to deal with wasted material on a big print.